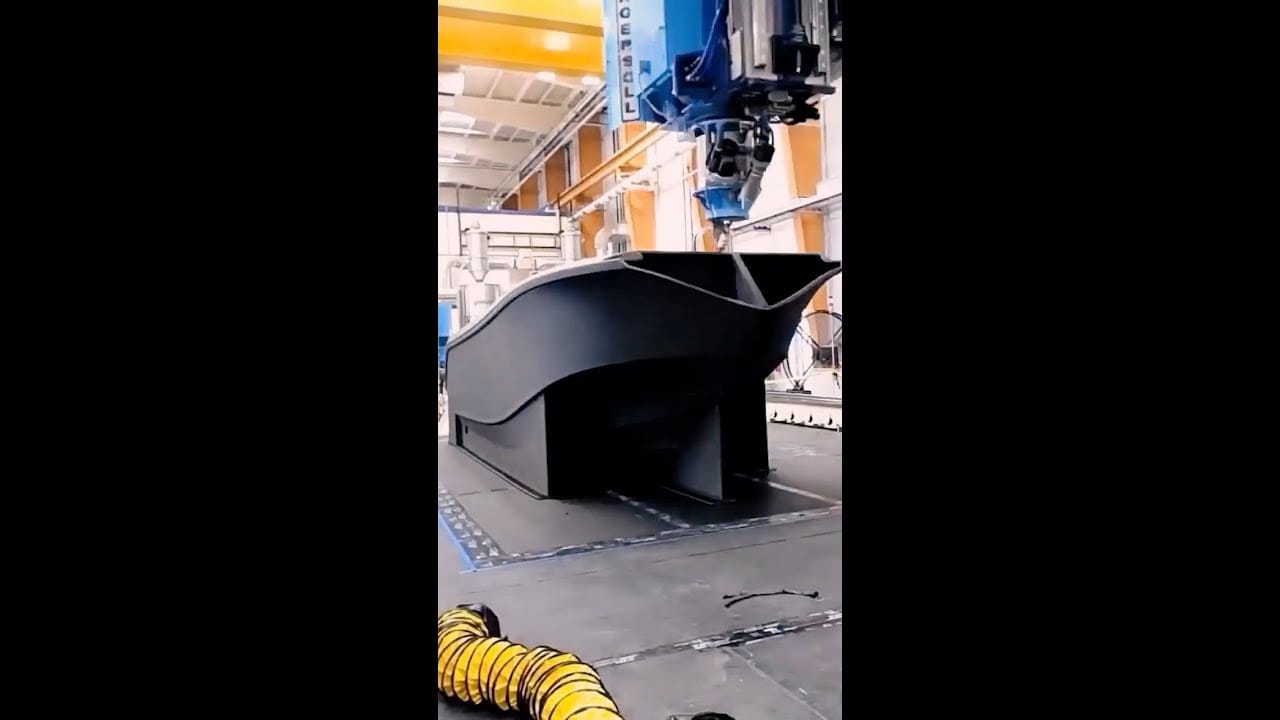

Unveiling Innovation: The Groundbreaking 3D Printing of the World’s Largest Polymer Boat!

Ingersoll MasterPrint, the world’s largest polymer 3D printer, is so big that it can produce objects up to 100 feet long.

source

3D Printing the Largest Polymer Boat Ever

In a groundbreaking achievement for the maritime and additive manufacturing industries, researchers and engineers have successfully 3D printed the largest polymer boat to date. This innovatively constructed vessel not only showcases the potential of 3D printing techniques but also opens new avenues for sustainability and design in marine engineering.

The Concept Behind 3D Printed Boats

The advent of 3D printing, also known as additive manufacturing, has transformed numerous sectors, allowing for rapid prototyping and customized production. In maritime applications, 3D printing offers significant advantages, such as reduced material waste, intricate design capabilities, and the potential for lightweight structures. The ability to print complex geometries that traditional boat-building methods cannot achieve is particularly valuable for enhancing performance and efficiency.

Engineering the Largest Polymer Boat

The recent project, undertaken by a collaborative team of engineers, designers, and researchers, aimed to demonstrate the scale and viability of 3D printed vessels. Utilizing advanced polymer materials, the boat was constructed using large-scale additive manufacturing techniques. This process involved layer-by-layer deposition of materials, allowing for precision and flexibility in design.

The boat measures an impressive length of over 30 feet, incorporating state-of-the-art marine-grade polymers designed to withstand the rigors of water travel. The team focused on ensuring that the vessel met safety standards, buoyancy requirements, and structural integrity to handle various marine environments.

Benefits of 3D Printing in Boat Design

Customization: One of the most significant advantages of 3D printing is the ability to tailor designs to specific needs. From personalized features to unique performance specifications, manufacturers can easily adapt designs, enhancing user satisfaction.

Material Efficiency: 3D printing minimizes waste by using only the material required for each component. This is particularly important in the boating industry, where traditional methods can result in significant scrap materials.

Reduced Construction Time: 3D printing greatly accelerates the construction timeline. What once took weeks or months can now be accomplished in days, enabling faster deployment of new designs and innovations.

- Sustainability: The use of eco-friendly polymers contributes to a more sustainable approach in manufacturing. Moreover, the potential for recycling and reusing materials opens doors for circular economy practices in the maritime sector.

Challenges and Future Prospects

Despite its advantages, the 3D printing of large-scale boats still faces challenges. Issues such as ensuring long-term durability and resistance to harsh marine conditions remain at the forefront of research. There are also considerations regarding regulatory approvals and safety standards that need to be addressed before such boats can be commercially produced.

Looking ahead, the success of the largest polymer boat serves as a catalyst for further exploration in 3D-printed marine vessels. Researchers are already exploring hybrid designs that combine traditional boat-building techniques with 3D printing, as well as experimenting with new materials that enhance performance and sustainability.

Conclusion

The creation of the largest polymer boat through 3D printing is a testament to the innovative spirit of the engineering and maritime communities. As technology continues to evolve, the potential for 3D printing to revolutionize boat design and manufacturing is immense, promising a future where sustainable, efficient, and customized marine vessels are not only a dream but a reality. The journey of this colossal boat marks just the beginning of what’s possible in the world of additive manufacturing for maritime applications.

Post Comment